Firearm and Gun Accessory Applications

Blast & Wash Systems can help with the right equipment for a small producer of handguns to a large scale international manufacturer of firearms and accessories.

Cardinal wheel blast systems offer a variety of cleaning methods to clean and prep parts for coatings and finishes. Using this automation ensures a consistent surface finish which means greater throughput and lower labor costs.

A variety of abrasives can be used to achieve the finish you are looking for – stainless steel, zinc, carbon steel and ceramic shot – engineered for your surface requirements

Cardinal blast equipment offers fast blast cycles, high production quality with consistent finish for your painting, deburring, anodizing, and coating needs. Perfect for Cerakote, Anodizing, DLC coatings, Black Nitride, and more!

Click here to watch the Cardinal Shot Show 2025 Showcase on Youtube

Advantages of Wheel Blast over Air Blast:

- Lower machine cost when automated

- Lower electrical consumption

- 3-5 times faster blast cycles

- No screw compressor

- Lower consumables

- Higher production

- More consistent Finish

- Less manual labor as opposed to Hand Cabinet

Available Equipment

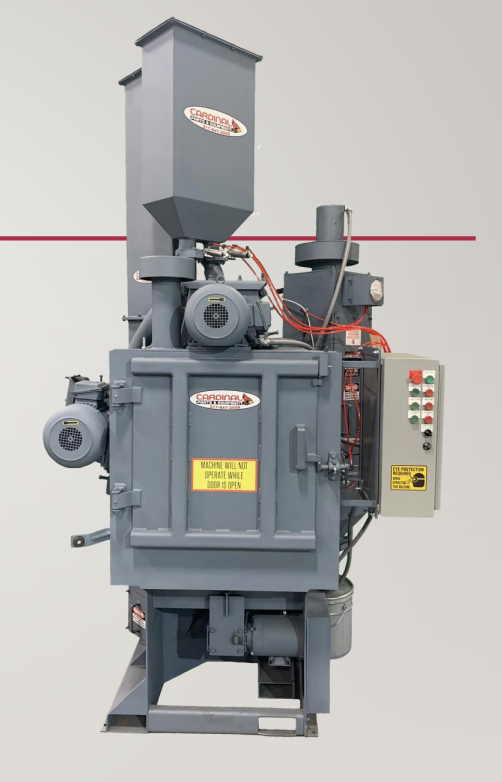

Cardinal 24 TW Table Blast

- 5 HP Blast Wheel side & top mount

- Max workload 400lb

- 24″ table with 27″ load height

- 19″ tall working blast zone on tree fixture

- Cast lined right wall

- VFDs for blast wheels

- Recipes for PLC (5 included)

- Low-level sensor

- Integrated 400CFM dust collector

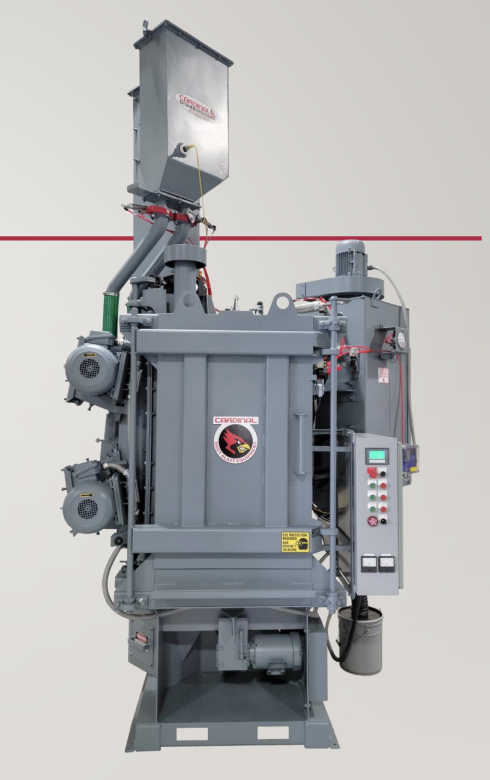

Cardinal 24XTS Table Blast

- (2) 5HP side mounted blast wheels

- Max workload 400lb

- 24″ table with 37″ load height

- 28″ tall working blast zone on tree fixture

- Cast lined right wall

- VFDs for blast wheels

- Recipes for PLC (5 included)

- Low-level sensor

- Integrated 800 CFM dust collector

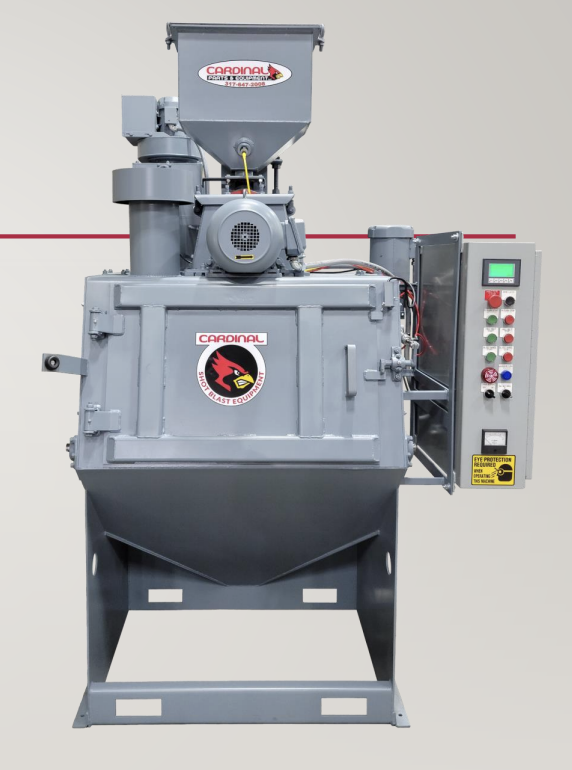

Cardinal 36XTS Table Blast

- 2 (5) HP side mounted blast wheels

- Blast wheel oscillation

- Max workload 1,000 lbs

- 36″ table with 27″ load height

- 28″ tall working blast zone on tree fixture

- Cast lined right wall

- VFDs for blast wheels

- Recipes for PLC (5 included)

- Low-level sensor with adder hopper

- Integrated 1200CFM dust collector

Cardinal 36XT3 Table Blast

- (3) 5HP mounted blast wheels

- Blast wheel oscillation

- Max workload of 1,000lbs

- 36″ table with 27″ load height

- 52″ tall working blast zone on tree fixture

- Cast lined right wall

- VFDs for blast wheels

- Recipes for PLC (5 included)

- Low-level sensor with adder hopper

- Integrated 1200CFM dust collector

Cardinal 150 Tumble Blast

- 5 HP blast wheel

- Max workload 150lb

- VFD blast wheel

- VFD mill belt

- Tight fitting front liners

- Recipes for PLC (5 included)

- Low-level sensor

- Integrated 400CFM dust collector

Cardinal 200 Tumble Blast

- 5 HP blast wheel

- Max workload 200lb

- VFD blast wheel

- VFD mill belt

- Tight fitting front liners

- Recipes for PLC (5 included)

- Low-level sensor

- Integrated 400 CFM dust collector

Cardinal 250 Tumble Blast

- 5 HP blast wheel

- Max workload 250lb

- VFD blast wheel

- VFD mill belt

- Tight fitting front liners

- Recipes for PLC (5 included)

- Low-level sensor

- Integrated 500 CFM dust collector

Cardinal 2460 Spinner Hanger

- (2) 7.5HP side mounted blast wheels

- 14″ rotary screen

- 20″ single lip separator

- Low-level sensor with adder hopper

- VFDs for blast wheels

- VFD for chamber and spinner drive

- Carousel walls fully cast lined

- Cast elevator buckets

- Recipes for PLC (5 included)

- Standalone 2000 CFM dust collector

- Standalone shot trap