Blast & Wash Systems proudly represent Diversitech Oil Mist

Filtration. For additional information please Contact Us.

Would you like to eliminate oil mist smoke & fumes in CNC turning, metal cutting or milling machines?

Before & after oil mist filtration

High-Efficiency Mist Collection for CNC Machines and Industrial Environments

In metalworking and machining operations, oil mist and oil smoke are common byproducts that can quickly compromise air quality, damage equipment, and pose serious health risks to workers. That’s where Diversitech’s line of oil mist collectors and oil mist eliminators comes in. Designed for high efficiency and durability, our mist collectors remove harmful mist and smoke particles from the air, especially those created by metalworking fluids and cutting oils used in CNC machines and other machine tools. Whether you need a mist collector for CNC machines or a complete oil mist filtration system for your entire facility, we have the right solution to keep your shop safe, clean, and compliant.

What Is an Oil Mist Collector?

An oil mist collector is a specialized air filtration system that captures airborne oil droplets and oil smoke generated during machining, grinding, and cutting operations. These mist collectors are typically mounted directly on CNC machines or integrated into the facility’s ambient air system. The result? Cleaner air, better visibility, fewer slippery surfaces, and a healthier environment for employees.

Applications for CNC Mist Collection

Oil mist is especially prevalent in high-speed machining and CNC machine operations where metalworking fluids are sprayed or flooded during the cutting process. These particles become airborne and can spread rapidly if not controlled. Diversitech’s CNC mist collectors are engineered to mount easily onto machine enclosures, capturing mist at the source and preventing it from escaping into the work environment. This mist collection at the point of generation improves efficiency and extends the life of your equipment.

Advanced Filtration Systems for Oil Mist Collection

Our oil mist filtration systems use multi-stage filter media to trap fine particles and return clean air back into your facility. These systems can also handle oil water separation, ensuring that collected fluids are properly managed and disposed of according to environmental guidelines.

Key Features of Our Oil Mist Collectors:

- High-efficiency capture of mist and smoke

- Easy installation on CNC and other machine tools

- Durable design for industrial environments

- Long-lasting, easy-to-replace filter media

- Compliance with air quality and safety standards

Whether you’re outfitting a single workstation or an entire production floor, our systems offer scalable solutions for effective mist collection.

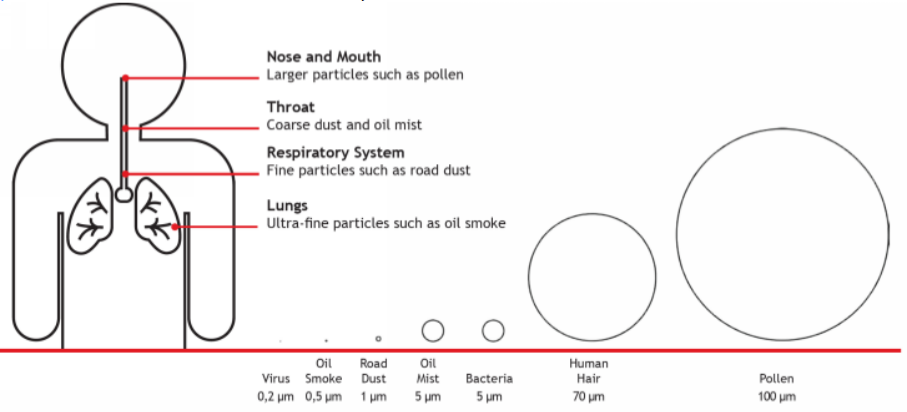

Did you know that oil mist and oil smoke?

∙ Contain particles as small as bacteria and viruses

∙ Contain small metal particles that can cause respiratory problems

∙ Contain material that can cause asthma

∙ Can affect lung function

∙ May cause skin problems such as oil acne and eczema

∙ Can increase the risk of slipping/falling injuries

Health and Safety issues are being taken very seriously by a growing number of companies as OSHA and the CDC Federal Agency standards increase. Many large US manufacturers are adopting European exposure limits as a global standard for their entire company and are exceeding OSHA Standards. To meet these standards companies must implement a highly efficient oil mist and oil smoke filtration system to filter out the particles. The exposure limits these companies are targeting range from .02 – 1 mg/m3 depending on company policy, well below the 5 mg/m3 standard set by OSHA. Older mist collector technology simply cannot provide these higher requirements and need a high tech and high efficiency unit to get reach these exposure limits.

∙ Oil smoke may cause lung diseases if inhaled.

∙ Oil smoke causes slippery floors and collects dust on machines and walls.

∙ Oil smoke can lead to coating in ventilation ducts that may cause fires.

∙ Oil smoke can cause coating in heat exchangers, reducing the efficiency of the heat recovery.

∙ The oil that is drained from the filter can be reused.