Downdraft Tables – Dry & Wet Filtration

Typical applications for downdraft tables would include:

- Welding smoke

- Metal grinding

- Deburring

Downdraft tables serve as dust collection from plastics and composite materials, odor control from gluing and painting, plasma cutting, powder mixing, soldering, and well as finishing processes (i.e. buffing and polishing).

Filter medias can be selected to control dust from woodworking, plastics, composites, metal grinding and welding, as well as dust from mixing, batching, and weighing.

Our tables are designed to:

- Exceed OSHA standards

- Offer quiet operation

- Ship fully assembled and ready to plug and play

Downdraft Tables – Dry Filtration

Many sizes to choose from – standard sizes and many options available.

*To read more about each unit please use the drop down menu below*

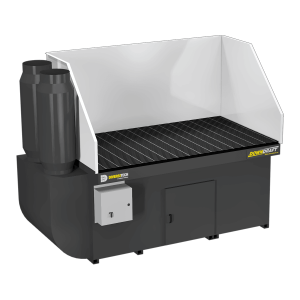

With a 2’x4′ ventilated worksurface, and plug & play 120V single-phase input power, this portable downdraft table series ensures flexible use as your pollution control needs change. These tables are fitted with industrial swivel castors, and an industry leading, high efficiency, nanofiber cartridge filter. Now any fumes, smoke, or dust from your shop activities can be captured right as they are produced, before compromising your indoor air quality.

WELDING, GRINDING, DEBURRING KIT INCLUDES:

- Side & Back Walls

- Metal Mesh Prefilter

- Grounding Lug

- 120V single phase

With a 2’x4′ ventilated worksurface, and a powerful 3.0 HP three-phase input power motor, this portable downdraft table series ensures flexible use as your pollution control needs change. These tables are fitted with industrial swivel castors, and an industry leading, high efficiency, nanofiber cartridge filter. Now any fumes, smoke, or dust from your shop activities can be captured right as they are produced, before compromising your indoor air quality.

PLASMA CUTTING KIT INCLUDES:

- Side & Back Walls

- 2″ Steel Bar Grating

- Slag Collection Baffle

- Vertical Metal Mesh Prefilter

- Exhaust Upblast & Silencer

The DD series industrial downdraft tables are the trusted choice of North America’s largest manufacturers. Heavy duty applications producing smoke, dust, or fumes can now be contained right at the source. With a ventilated work surface 3′ deep by 4′ wide (DD-3X4) can be configured to suit dozens of industrial applications. As standard, the table comes fitted with a multi-stage spark arrestance baffle, dual 8″ exhaust silencers, and an automatic reverse-pulse filter cleaning system.

WELDING, GRINDING, DEBURRING KIT INCLUDES:

- Side & Back Walls

- Metal Mesh Prefilters (4)

- Nanotech XV high-efficiency Primary Filters (2)

- Grounding Lug

Choosing the right primary filter will depend on the type of chemical fumes or overspray to be contained. Below are some general guidelines, but do Contact Us if you would like our Application Engineers to recommend a filtration setup, specific to your application.

- PolyTech Cartridge

- NanoTech Cartridge

- Paint Arrestor – Paint Arrestor media can be installed as pre-filter (under grate), and/or as a primary filter (wrapped around a perforated canister).

- Spunbond polyester, water washable, best for wet/sticky spray applications

- Nanofiber, high efficiency, best for applications with a mix of dust and fumes

- Low-cost, disposable filter media prevents overspray from clogging filters

This version of our 3’x4′ Downdraft Table is designed to contain odors, fumes, and especially Volatile Organic Compounds (VOC) from activities like spray painting, varnishing, coating, or working with solvents and adhesives. The side-mounted canister-type afterfilter, filled with exuded activated carbon, allows for indoor re-circulation while protecting air quality.

The VOC kit upgrades the our downdraft table with:

- Explosion-Proof Motor, Class 1: Group C/D

- Exhaust upblast module, afterfilter clamp

- Two CarboTech carbon canister afterfilters, reversible

- 100lbs x2 of extruded activated carbon, w/20mm filter wrap

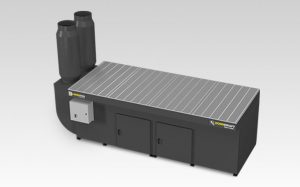

The DD series industrial downdraft tables are the trusted choice of North America’s largest manufacturers. Heavy duty applications producing smoke, dust, or fumes can now be contained right at the source. With a ventilated work surface 3′ deep by 6′ wide (DD-3X6) can be configured to suit dozens of industrial applications. As standard, the table comes fitted with a multi-stage spark arrestance baffle, dual 10″ exhaust silencers, and an automatic reverse-pulse filter cleaning system.

WELDING, GRINDING, DEBURRING KIT INCLUDES:

- Side & Back Walls

- Metal Mesh Prefilters (6)

- Nanotech XV high-efficiency Primary Filters (2)

- Grounding Lug

Built to withstand tough applications, Diversitech’s DD series of industrial downdraft tables are the trusted brand of North America’s largest manufacturers. The DD 3′ X 8′ (3′ deep by 8′ wide) ventilated work surface captures fumes, smoke and dust right at source. Cleaner indoor air is guaranteed.

The DD 3′ X 8′ can be configured to suit dozens of industrial applications. The table comes equipped with a multi-stage spark arrestance baffle for fire prevention and dual 10” exhaust silencers for noise reduction. Its automatic reverse-pulse filter cleaning system helps cut down on overall maintenance requirements.

The DD series of industrial tables can be built-to-order in almost any configuration. Whether you weld, grind, debur, cut, sand, finish, solder, paint or mix, the DD 3′ X 8′ Downdraft Table provides the perfect, flexible, all-in-one solution.

Features

- Flexible 96” x 42” Worksurface

- High Capture Face Velocity (330 FPM)

- Multi-stage Spark Arrestance Baffling

- Automatic Reverse Pulse Self-cleaning System

- Dual 10” Exhaust Silencers

- Dust Drawer for easy servicing

Benefits

- Hands-free, capture-at-source

- Low maintenance, automatic self-cleaning system included

- Compliant with OSHA guidelines for safe capture of dust, smoke and weld fumes

Options

- 3” Swivel Casters, set of six

- Blue Cushion Grid Matting (96” X 36”)

- Minihelic Gauge

- Dual-HEPA Afterfilter (with frame)

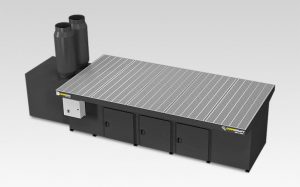

The trusted choice of North America’s largest manufacturers, Diversitech’s DD series of industrial downdraft tables are built to withstand the most demanding applications. With a ventilated, dual-sided work surface, 4′ deep by 4′ wide, you can configure the DD 4′ X 4′ to suit dozens of industrial applications. Fumes, smoke and dust are captured right at source so indoor air quality remains uncompromised.

As standard, the table comes fitted with multi-stage spark arrestance baffle for fire prevention and dual 10” exhaust silencers for noise reduction. An automatic reverse-pulse filter cleaning system reduces overall maintenance requirements.

The DD series of industrial tables can be built-to-order in almost any configuration. Whether you weld, grind, debur, cut, sand, finish, solder, paint or mix, the DD 4′ X 4′ Downdraft Table provides the perfect, flexible, all-in-one solution.

Features

- Flexible, Dual-sided 48” x 48” Worksurface

- High Capture Face Velocity (425 FPM)

- Multi-stage Spark Arrestance Baffling

- Automatic Reverse Pulse Self-cleaning System

- Dual 10” Exhaust Silencers

- Dust Drawer for easy servicing

Benefits

- Hands-free, capture-at-source

- Low maintenance, automatic self-cleaning system included

- Compliant with OSHA guidelines for safe capture of dust, smoke and weld fumes

Options

- 3” Swivel Casters, set of four

- Blue Cushion Grid Matting (48” X 48”)

- Minihelic Gauge

- Dual-HEPA Afterfilter (with frame)

Tough enough to hold up under the most demanding applications, Diversitech’s DD series of industrial downdraft tables are the trusted brand for North America’s largest manufacturers. Its 4′ deep by 6′ wide, ventilated, dual-sided work surface captures contaminants right at source. Air quality remains uncompromised.

Equipped with a multi-stage spark arrestance baffle for fire prevention and dual 10” exhaust silencers for noise reduction, you can configure the DD 4′ X 6′ to suit many industrial applications. Its automatic reverse-pulse filter cleaning system helps keep overall maintenance requirements down.

Built-to-order in almost any configuration, the DD 4′ X 6′ provides the perfect, flexible, all-in-one solution. Ideal applications include: welding, grinding, deburring, cutting, sanding, finishing, soldering, painting or mixing.

Features

- Flexible, Dual-sided 48” x 72” Worksurface

- High Capture Face Velocity (325 FPM)

- Multi-stage Spark Arrestance Baffling

- Automatic Reverse Pulse Self-cleaning System

- Dual 10” Exhaust Silencers

- Dust Drawer for easy servicing

Benefits

- Hands-free, capture-at-source

- Low maintenance, automatic self-cleaning system included

- Compliant with OSHA guidelines for safe capture of dust, smoke and weld fumes

Options

- 3” Swivel Casters, set of six

- Blue Cushion Grid Matting (48” X 72”)

- Minihelic Gauge

- Dual-HEPA Afterfilter (with frame)

Durable and dependable, the DD 4′ X 8′ Downdraft Table is built to withstand the most demanding applications. Its 4′ deep by 8′ wide, ventilated, dual-sided work surface collects airborne toxins right at source. Shop air remains uncompromised.

Equipped with a multi-stage spark arrestance baffle for fire prevention and dual 10” exhaust silencers for noise reduction, you can build-to-order the DD 4′ X 8′ in almost any configuration. Its automatic reverse-pulse filter cleaning system reduces overall maintenance requirements.

Whether you weld, grind, debur, cut, sand, finish, solder, paint or mix, the DD 4′ X 8′ Downdraft Table provides the perfect, flexible, all-in-one solution.

Features

- Flexible, Dual-sided 48” x 96” Worksurface

- High Capture Face Velocity (300 FPM)

- Multi-stage Spark Arrestance Baffling

- Automatic Reverse Pulse Self-cleaning System

- Dual 10” Exhaust Silencers

- Dust Drawer for easy servicing

Benefits

- Hands-free, capture-at-source

- Low maintenance, automatic self-cleaning system included

- Compliant with OSHA guidelines for safe capture of dust, smoke and weld fumes

Options

- 3” Swivel Casters, set of eight

- Blue Cushion Grid Matting (48” X 96”)

- Minihelic Gauge

- Dual-HEPA Afterfilter (with frame)

The DD series of industrial downdraft tables handles even the most demanding applications. Capturing smoke, fumes and dust right as they’re produced, the DD 5×10 Downdraft Table comes with a ventilated 5′ deep by 10′ wide, dual-sided work surface. Indoor shop air remains clear of airborne toxins.

You can configure the DD 5′ X 10′ to suit many different industrial applications. Its multi-stage spark arrestance baffle prevents workplace fire and its dual 10” exhaust silencers reduce shop noise. Overall maintenance requirements are kept low thanks to its automatic reverse-pulse filter cleaning system.

Built-to-order in almost any configuration, the DD 5′ X 10′ Downdraft Table provides the perfect, flexible, all-in-one solution. Whether you weld, grind, debur, cut, sand, finish, solder, paint or mix, Diversitech DD series of industrial downdraft tables can fill your needs.

Features

- Flexible, Dual-sided 60” x 120” Worksurface

- High Capture Face Velocity (330 FPM)

- Multi-stage Spark Arrestance Baffling

- Automatic Reverse Pulse Self-cleaning System

- Dual 10” Exhaust Silencers

- Dust Drawer for easy servicing

Benefits

- Hands-free, capture-at-source

- Low maintenance, automatic self-cleaning system included

- Compliant with OSHA guidelines for safe capture of dust, smoke and weld fumes

Options

- 3” Swivel Casters, set of eight

- Blue Cushion Grid Matting (60” X 120”)

- Minihelic Gauge

- Dual-HEPA Afterfilter (with frame)

Wet Downdraft Tables

The MONSOON™ Wet Downdraft Table product series delivers the safe capture of hazardous/combustible dusts with the smallest equipment footprint in the industry. This self-contained wet downdraft table’s patent-pending design achieves a very high face-velocity at a very affordable price.

A wide range of application kits and custom fittings can help you meet your NFPA and OSHA requirements.

The MONSOON™ series all include industrial swivel casters, adding mobility and versatility to your application. This wet filtration table is perfect for capturing combustible dust, including mixtures of steel, aluminum, titanium, and magnesium.

The MONSOON™ works by drawing dust-laden air through the table surface and into a cascading water bath. The wet downdraft table cleans the air by using the combined action of centrifugal force and a thorough intermixing of water and dust laden air. The dust is separated from the airstream by water droplets created by the flow of air through strategically placed baffle plates. Once wet, the dust becomes permanently trapped and falls down into a reservoir

*To read more about each unit please use the drop down menu below*

Cost-effective yet high-performing, the Monsoon Mini Wet Downdraft Table safely captures combustible dust at source. Requiring no permanent ducting or central installation, its compact, self-contained, patent-pending design achieves a high-face velocity at a very affordable price.

To safely collect dangerous combustibles, the Monsoon Mini pulls contaminated air through its ventilated work surface and moves them into a water torrent. Once bonded with water droplets, the dust particles drain down to the bottom of the collector for safe removal. Interior baffling creates the required turbulence to maximize filtration efficiency while preventing water vapor from leaving the exhaust, avoiding excess humidity.

With an extremely small equipment footprint, the Monsoon Mini Wet Downdraft Table comes fitted with heavy duty castors for portability. The cabinet’s stainless steel construction guards against corrosion and the collector’s internal components can be removed for easy cleaning.

Designed for the safe collection of combustible metal dusts, ideal applications include: aluminum, magnesium, titanium, grinding & deburring, sanding & finishing, 3D printing, chemical dust and buffing.

Features

- Flexible 30” x 36” Worksurface

- High Capture Face Velocity (300 FPM)

- 3 HP TEFC Motor producing 1200 CFM of Airflow

- Stainless Steel Anti-corrosion Construction

- Low Water auto-shutdown

- Blue Rubber Grid Matting

- Manual Water Refill

Options

- Auto Wash-down System

- WV-55 Sludge-Vac

- Side and Back Walls

- HEPA Afterfilter Kit (99.99% @ 0.3 micron)

- Dust-Tight / Vapor-Tight Light Kit

- Auto-fill Water Control System

- Custom configurations available on request

Benefits

- Capture-at-source for cleaner air

- Industrial swivel castors included for portability

- Compliant with NFPA guidelines for combustible dust

Designed for the safe removal of hazardous combustible dust, the Monsoon 3′ X 4′ Wet Downdraft Table is one of the most high-performing, cost-effective, wet dust collection solutions on the market. Equipped with a powerful integrated blower, its high capture velocity collects more contaminants from a wider surface area, than other competing models.

The Monsoon 3’ x 4’ safely captures combustibles by pulling contaminated air through the ventilated work surface and moving them into a torrent of water. The dust particles then bond with suspended water droplets before draining down to the bottom of the collector for safe removal.

The Monsoon 3’ x 4’ Wet Downdraft Table’s plug and play design allows for quick and easy installation. The cabinet’s stainless steel construction guards against corrosion and the collector’s internal components can be removed for easy cleaning. A protective rubber grid mat comes included to protect delicate parts from damage.

Designed for the safe collection of combustible metal dusts, ideal applications include: aluminum, magnesium, titanium, grinding & deburring, sanding & finishing, 3D printing, powder mixing and plastic dust.

Features

- Flexible 49” x 36” Worksurface

- High Capture Face Velocity (250 FPM)

- 5 HP TEFC Motor producing 3000 CFM of Airflow

- Stainless Steel Anti-corrosion Construction

- Auto-Level Water Control System

- Standard Rubber Cushion Grid Mat

- Standard Exhaust Silencer

Options

- Auto Wash-down System

- WV-55 Sludge-Vac

- Side and Back Walls

- HEPA Afterfilter Kit (99.99% @ 0.3 micron)

- Dust-Tight / Vapor-Tight Light Kit

- Custom configurations available on request

Benefits

- Capture-at-source for cleaner air

- Industrial swivel castors included for portability

- Compliant with NFPA guidelines for combustible dust

- Integrated overhang for seated operations

- Self-contained, compact design

The Monsoon 3’ x 6’ Wet Downdraft Table is one of the most high-performing, cost effective wet dust collection solutions on the market. Safely capturing combustible dust at source, the Monsoon 3’ x 6’ Wet Downdraft Table has one of the smallest equipment footprints in the industry. Its self-contained design achieves a high-face velocity at a very affordable price.

The Monsoon 3’ x 6’ safely captures combustibles by pulling contaminated air through the ventilated work surface and moving them into a torrent of water. The dust particles then bond with suspended water droplets before draining down to the bottom of the collector for safe removal.

The Monsoon 3’ x 6’ Wet Downdraft Table comes equipped with an Auto-Water Level Control System that automatically maintains correct water levels in the basin. The cabinet’s stainless steel construction guards against corrosion and the collector’s internal components can be removed for easy cleaning.

Designed for the safe collection of combustible metal dusts, ideal applications include: aluminum, magnesium, titanium, grinding & deburring, sanding & finishing, powder mixing and buffing.

Options

- Auto Wash-down System

- WV-55 Sludge-Vac

- Side and Back Walls

- HEPA Afterfilter Kit (99.99% @ 0.3 micron)

- Dust-Tight / Vapor-Tight Light Kit

- Custom configurations available on request

Features

- Flexible 73” x 36” Worksurface

- High Capture Face Velocity (230 FPM)

- 10 HP TEFC Motor producing 5000 CFM of Airflow

- Stainless Steel Anti-corrosion Construction

- Auto-Level Water Control System

Benefits

- Capture-at-source for cleaner air

- Industrial swivel castors included for portability

- Compliant with NFPA guidelines for combustible dust

- Small foot-print, easy to use

Safely capturing contaminants at source, the Monsoon 3’ x 8’ Wet Downdraft Table provides an all-in-one solution for the collection of combustible metal dusts. Its self-contained design achieves a high-face velocity and requires no permanent ducting or central installation.

The Monsoon 3’ x 8’ safely captures combustibles by pulling contaminated air through the ventilated work surface and moving them into a torrent of water. The dust particles then bond with suspended water droplets before draining down to the bottom of the collector for safe removal. Interior baffling creates the required turbulence to maximize filtration efficiency. A mist-eliminator afterfilter prevents the unit from exhausting humidity and water into the workspace.

The Monsoon 3’ x 8’ Wet Downdraft Table includes a 12” integrated extended overhang that allows operators to sit ergonomically at the table surface. The cabinet’s stainless steel construction guards against corrosion and the collector’s internal components can be removed for easy cleaning.

Designed for the safe collection of combustible metal dusts, ideal applications include: aluminum, magnesium, titanium, grinding & deburring, sanding & finishing, powder mixing and buffing.

Options

- Auto Wash-down System

- WV-55 Sludge-Vac

- Side and Back Walls

- HEPA Afterfilter Kit (99.99% @ 0.3 micron)

- Dust-Tight / Vapor-Tight Light Kit

- Custom configurations available on request

Benefits

- Capture-at-source for cleaner air

- Industrial swivel castors included for portability

- Compliant with OSHA and NFPA guidelines for combustible dust

- Small foot-print, easy to use

- Removable water-tree for easy cleanout

Features

- Flexible 96” x 36” Worksurface

- High Capture Face Velocity (230 FPM)

- 15 HP TEFC Motor producing 6500 CFM of Airflow

- Stainless Steel Anti-corrosion Construction

- Auto-Level Water Control System