TRANSMET’S ZINC SHOT VS OTHER ABRASIVES

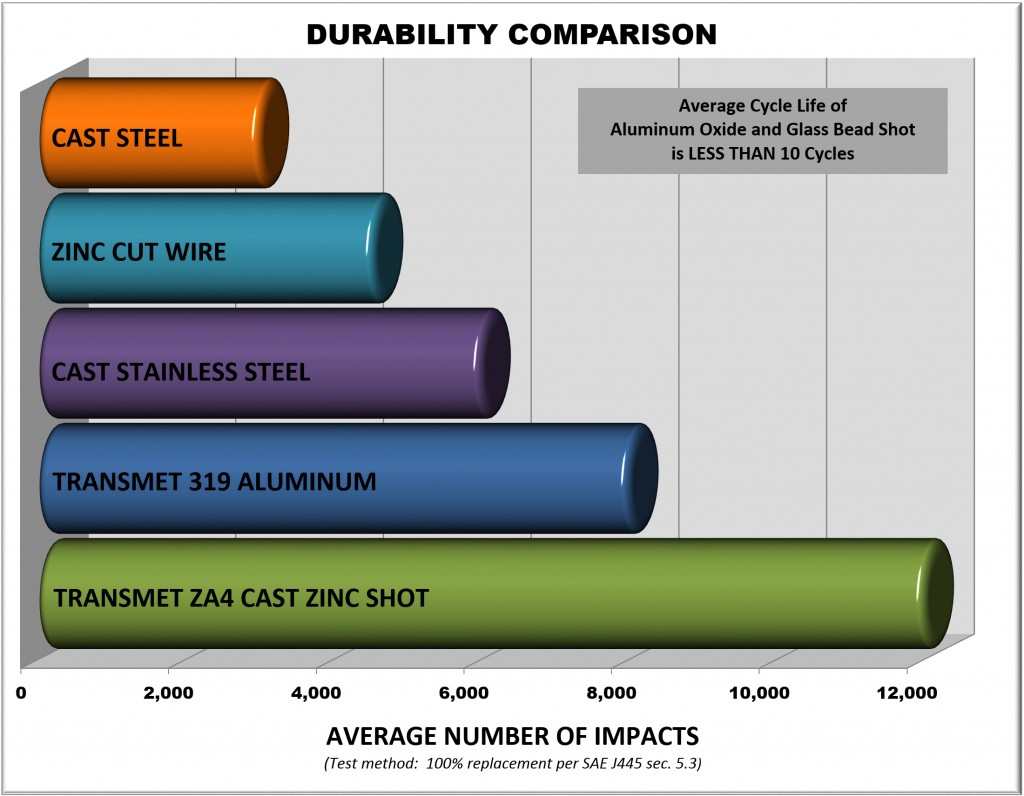

Transmet’s unique casting process results in high durability, long-lasting blast media proven to outlast alternatives. Cast Zinc Shot lasts 2x longer than stainless steel, 3x longer than zinc cut wire, 4x longer than steel shot, and 10,000x longer than glass bead and aluminum oxide.

TRANSMET’S ALUMINUM SHOT VS OTHER ABRASIVES

Transmet’s unique casting process results in high durability, long-lasting abrasive proven to outlast common abrasives. Cast Aluminum Shot lasts longer than stainless steel, almost 2 times longer than zinc cut wire, almost 3 times longer than steel shot, and 1,000 times longer than glass bead and aluminum oxide abrasive.

APPLICATIONS FOR CAST ZINC SHOT

Transmet Cast Zinc Shot Blast Media is ideal for shot blasting (or abrasive

blasting) applications including surface finishing of castings, deburring, flash removal, corrosion removal, paint removal, coating removal, and more.

APPLICATIONS FOR CAST ALUMINUM SHOT

Transmet Cast Aluminum Shot Abrasives is ideal for shot blasting (or abrasive blasting) applications including surface finishing of castings, deburring, flash removal, corrosion removal, paint removal, coating removal, and more.

More applications: profiling for coating & lubrication adhesion, blast cleaning parts during remanufacture, refractory mold release removal from dies, and more.

Transmet Cast Zinc Shot significantly reduces damage and wear on high-wear

internal components like the impeller, control cage, wheel liners, blast wheel and blades. Cabinet wear as a whole is virtually eliminated.

This blast wheel has been exclusively running RSZ-850-ZA4 Cast Zinc Shot for

16,200 hours!

RAPIDLY SOLIDIFIED METALS

Transmet primary products are very pure Aluminum Flakes, Cast Aluminum Shot Blast Media, and Cast Zinc Shot Blast Media. Learn about Transmet Product Applications or explore all Transmet Products.

Stainless Steel Shot and Grit Abrasives

Stainless steel shot is used for cleaning, deburring, descaling and surface finishing for aluminum and non-ferrous alloy castings, molds and fabrications. Stainless steel shot offers cost performance savings over stainless steel cut wire shot, aluminum shot, zinc shot, glass beads and ceramic beads.

Cast stainless steel grit is used for surface preparation prior to coating, surface finishing, oxide layer removal, natural stone finishing and investment casting finishing. It is a very aggressive abrasive media with a hardness of approx. 62 HRC, and is a proven alternative to aluminum oxide, garnet and other mineral abrasives.

Vulkan Blast Shot

Vulkan Blast Shot

Vulkan Blast Shot is a leader in the North American abrasives market offering highly qualified sales reps, engineers and technicians to assist you in making the right choice, the BEST choice, for your abrasive media needs. As an added benefit, Vulkan customers also get COMPLIMENTARY on site machine evaluations to ensure the highest level of blasting efficiency.

CHRONITAL®

Non-rusting cast stainless steel shot available in various sizes.

GRITTAL®

Non-rusting cast stainless steel grit available in various sizes and two hardnesses.