Vapor Honing

Vapor Honing

Wet Blasting Equipment & Vapor Blasting Services

Blast & Wash Systems has partnered with Vapor Honing Technologies & Force Automation to deliver the next great thing in advanced robotic wet blasting.

No matter the size or weight of a part, we can customize a system to meet your needs, whether it be a single or multi part process. With a fine-tuned combination of abrasive media and robotic accuracy, we can greatly increase throughput and eliminate defective parts.

What is Vapor Honing?

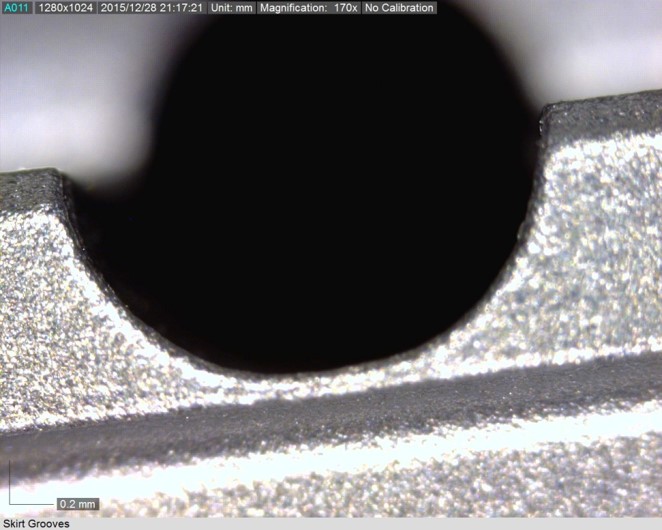

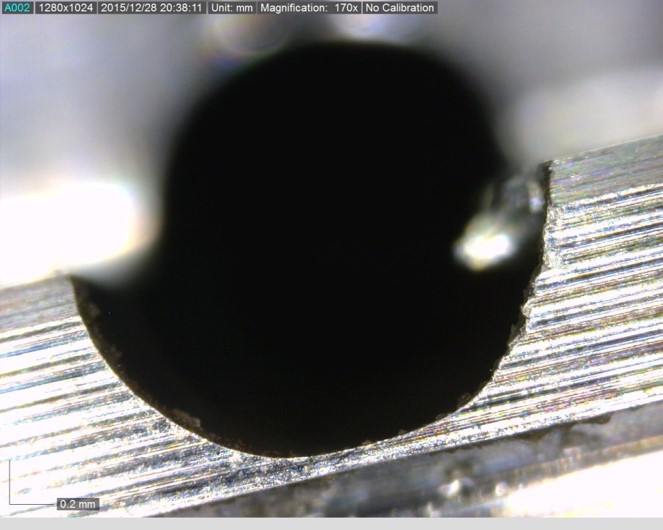

- Combining water and abrasive together forms a slurry which is propelled at the part surface using compressed air.

- Abrasive selection is made based on desired surface roughness or aesthetical finish.

How is it different?

- Cleans by flow not impact

- Can blast with the finest abrasives (1200 Mesh)

- Dust Free

- Chemical Free

- Blast and de grease in one simple step

What makes Vapor Honing different ?

- Wide range of product offering

- Products carry a Lifetime warranty

- Large company ability small company agility

Equipment Features?

- Media Density Meter

- Polyurethane Pump Impeller

- LED Cabinet Lighting

- Stainless Steel Construction (MIG or TIG)

- HDPE Plastic

- Heated Sump

- Manual Turntables

Applications?

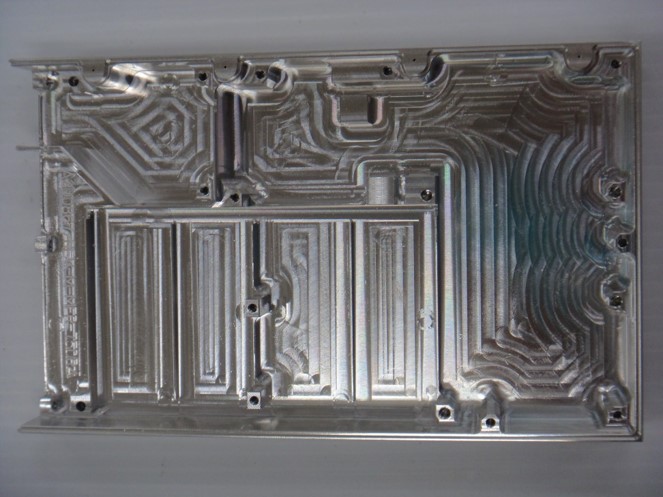

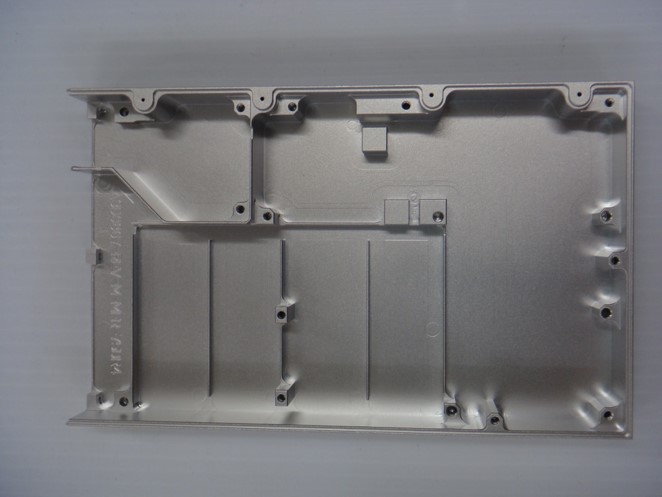

- Re Manufacturing

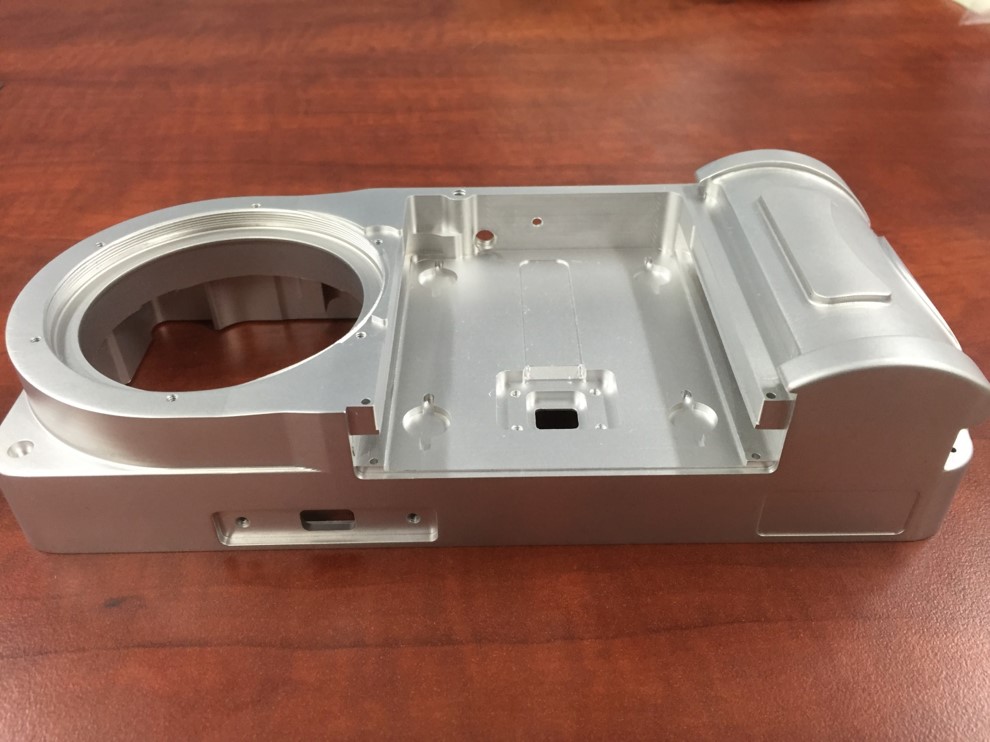

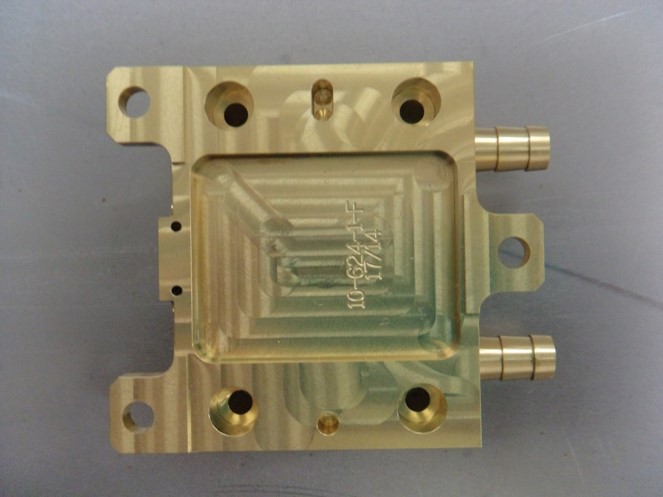

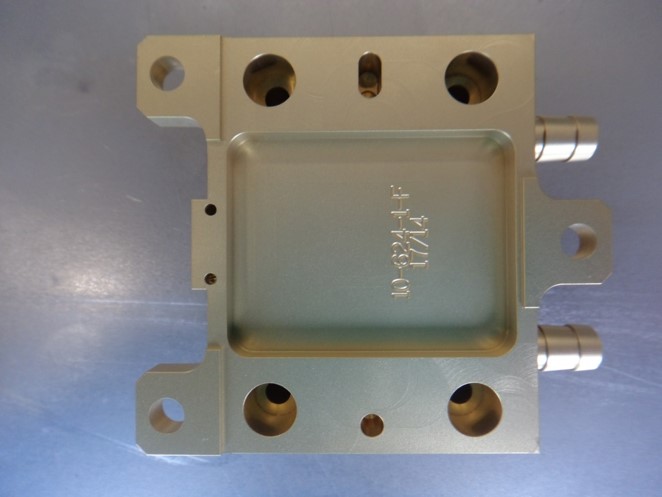

- CNC Machining

- Coating Prep

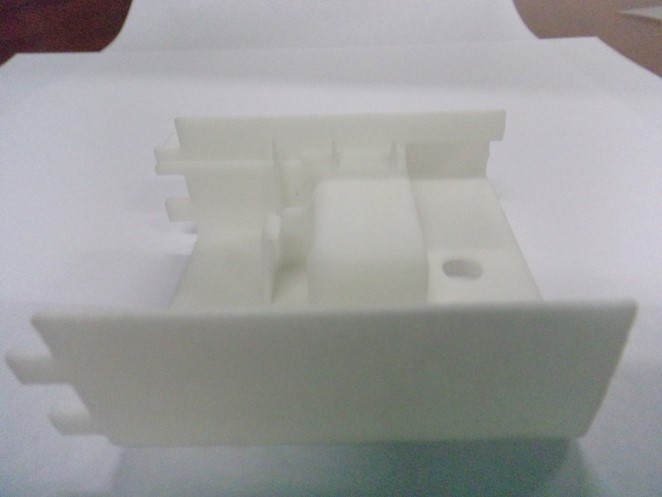

- Additive Manufacturing

- Restoration