PIPE & TUBE (ID & OD) BLASTING SYSTEMS & SPRAY COATING SYSTEMS

Considered leaders in the field of pipe surface preparation, SBS has designed and built automated pipe blasting systems for pipes ranging from 2″ to 30″ in diameter and up to 50 feet long. Working with nearly all of the oil industry exploration manufacturers (Halliburton, NOV, Baker Hughes, GE, Oil Lift, PV Fluids, Tierra Alta, and more), SBS pipe & tube blasters are robust, reliable, and high speed production machines. Whether your needs are for high throughput or simply process improvement, SBS will design your pipe & tube blasting system and spray coat systems to meet your needs.

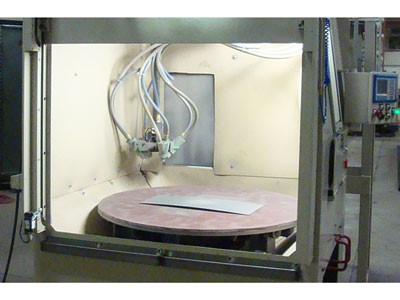

ROTARY STYLE BLASTING SYSTEMS

A turntable blasting machine offers the ability to blast a wide variety of parts and can easily be integrated with hand holes to optimize the machine for maximum use. Turntables can be fixed inside the cabinet for maximum cleanliness and for reduced plant space or can be mounted to a shuttle system to move them in and out of the machine for ease of loading and unloading. Whether fully automated or completely manual, Surface Blasting Systems will design your turntable to meet your needs.

PASS THRU & CONVEYOR STYLE BLASTING SYSTEMS

A pass-thru or conveyor style blasting machine offers the ability to blast a continuous supply of product with little to no adjustments. Product is generally fed into the machine via a conveyor from one end of the machine, passes through the blasting zone in front of fixed or mobile blasting guns or wheels and exits through an outfeed conveyor. Pass-thru type equipment is beneficial to a facility where integration into an existing manufacturing line is desired. The machines can easily be adapted to communicate with surrounding equipment to ensure continuous product flow. From I-Beams to glass etching, Surface Blasting Systems will design a pass-thru system to meet your needs

FIXED STATION & ROBOTIC STYLE BLASTING SYSTEMS

Used heavily in the aerospace and automotive industries, fixed station or robotic blasting systems are machines where the part is loaded into the machine (either automatically or manually) and once inside the machine, is stationary. A robotic gun nozzle handles all the motion necessary to blast the entirety of the part to be blasted based on preconfigured recipes or paths. Robotic systems are best suited for parts that are complex and/or delicate. Full 8 axis capable robots can be utilized for nearly any application and for the most complex of blasting requirements.

Wash Systems

- Customized for blasting single or multiple parts

- Customizable cabinet size

- Automated robotic system with teach pendant

- Available options: Filtration, HMI controls, auto rinse & blow off dry stage.