Remanufacturing / Auto

Blast & Wash Systems offers a variety of cleaning systems for blast, wash and deburr for the automotive reman industry.

Finishing of typical parts:

- Brakes

- Electrical parts

- Axles

- Engine components

- Complete engine assemblies

- Hydraulics, Pumps

- Transmission Equipment

- Wheel bearings

- Fuel injection components

- Cylinder heads

- Car wheels

- Truck wheels

- Gears

The one thing that all of these parts or components have in common is that they all must be cleaned of residue or prepped for paint prior to remanufacturing.

Blast & Wash Systems offers a complete line of equipment to help you in every step of cleaning with manual or automated cleaning systems:

- Dry Blast Cabinets – manual air or automated blast cleaning

- Wet Blast Cabinets – manual or automated

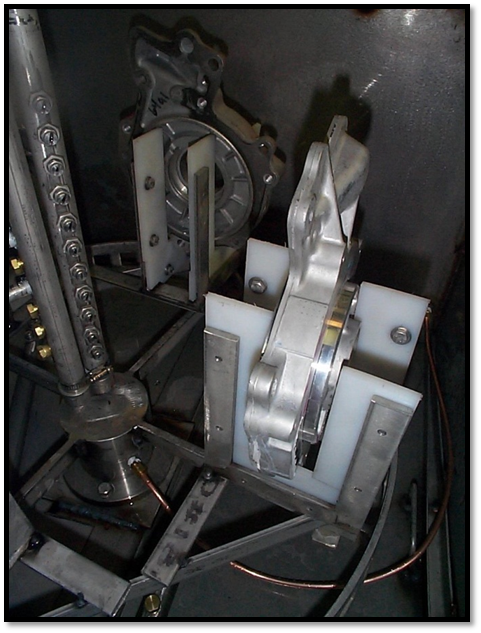

- Wheel Blast Systems- tumble, table, pass through, and spinner

- Parts washers – dip tanks, spray cabinets, belt washers, ultrasonic cleaning

- Vibratory – deburr, burinsh, polish

There are three types of blast cleaning equipment, air blast, wet blast and wheel blast, often referred to as airless blast.

Air blast propels the media with high velocity compressed air.

Wet blast offers cleaning with suspended abrasive media in water giving a softer blast for sensitive parts.

Wheel blast propels the media via a motor direct drive and is 7 times faster than compressed air blasting.

Remanufacturing is the rebuilding of a product to specifications of the original manufactured product using a combination of reused, repaired and new parts. It requires the repair or replacement of worn out or obsolete components and modules. Parts subject to degradation affecting the performance or the expected life of the whole are replaced. Remanufacturing is a form of a product recovery process that differs from other recovery processes in its completeness: a remanufactured machine should match the same customer expectation as new machines.

For additional questions regarding remanufacturing please email sales@blast-wash-systems.com or Contact Us.