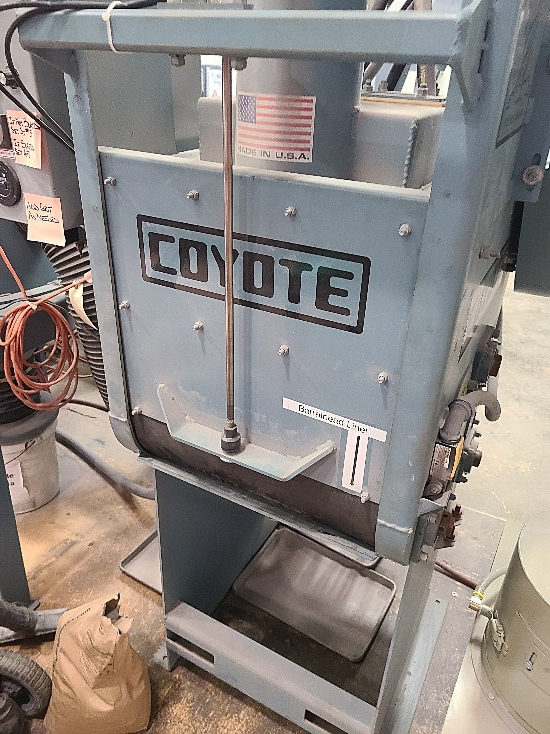

Coyote 1.25 Air Belt Blast & Recovery System

complete with 600 CFM dust collector

Standard Features:

- (3) Blast Nozzles

- System new in 2021

- Max Workload 150lb

- Electrical 230v 3 Phase

- Continuous Molded Rubber Belt

- VFD on mill belt drive

- Low Noise Level

- Safety Interlocks

- Reversing Mill Belt

- Automatic Timer Controls

- Low Profile Design

Our Price: $29,000

Purchase Order, Deposit, Final Balance

needs to be made out and paid to:

Blast & Wash Systems

9401 State Rte 21 Wayland, NY 14572

Air Blast System

Air Blast Nozzles: Three 3/8″ diameter Venturi carbide nozzles with 3/16″ diameter air jets are standard. Full coverage of blast chamber is accomplished. Height of nozzles to the work is adjustable.

Cabinet Construction

Cabinet: Formed to maintain structural integrity. The cabinet is fabricated from 1/4″ steel plate. Access holes in sides of cabinet to simplify belt replacement. Access door in back of cabinet permits removal of trapped material collected on abrasive screen.

Door: One piece polyurethane door opens and closes easily and provides full access to blast chamber Door is positively sealed from abrasive and dust leakage.

Work Loading Height: 40″

Work Load Capacity: 17″ wide x 20″ diameter mill will handle 1.25 cubic feet or 150 LBS.

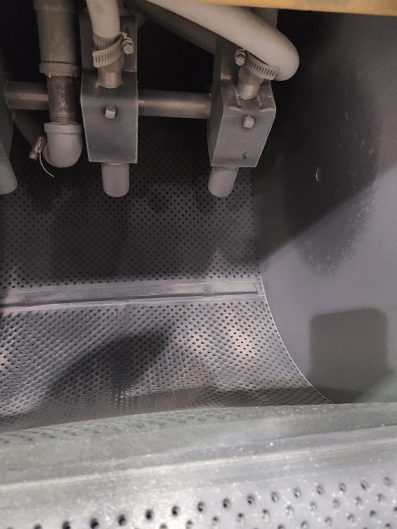

Conveyor: Continuous molded rubber tumble belt is (2) ply construction with 1/8″ diameter abrasive drain holes. Rubber tumbling ridges are molded directly onto the belt.

Conveyor Rollers: Rollers have 1 3/16″ diameter solid shafts. All rollers are mounted to the cabinet with standard (4) bolt flange bearings.

Conveyor Speed: 4.8 feet per minute.

Power and Air Requirements

Electric Motors: All motors are totally enclosed and fan cooled to provide maximum life. Unit optionally equipped – 230-460 volt – 3 phase.

Electric Motors: All motors are totally enclosed, fan cooled, to provide maximum life.

Mill Drive: 1/2 HP, 1800 RPM

Air Requirement: 100-120 CFM @ 60-80 PSI. 3/4″ NPT furnished for air connection.

Separator System

Abrasive Screening: Abrasive screening in cabinet eliminates tramp material from abrasive.

Abrasive Separator: 600 CFM centrifugal for optimum sizing of contaminate removal.

Abrasive Required: 50 pounds for initial start-up.

Dust Collector: 600 CFM, minimum required.

Safety and Structure

Safety: Blast nozzles operational only when door is closed. Chain drive is fully guarded.

Noise Level: Approximately 80 DB

Shipping Weight: 1,100 pounds

Machine Dimensions: 29″ wide x 37″ deep x 69″ tall