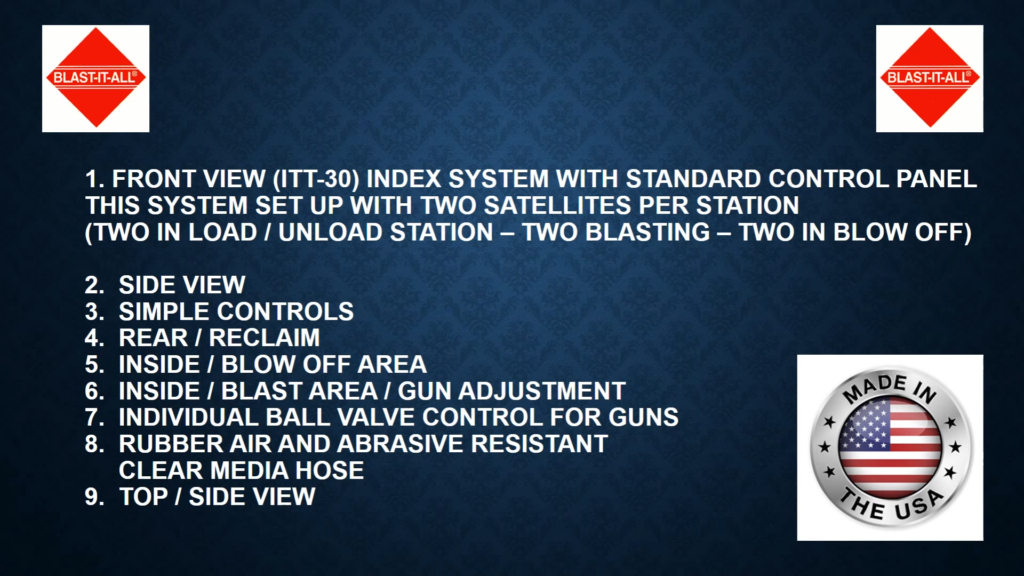

Blast & Wash Systems will be an exhibitor at EASTEC, New England’s premier manufacturing exposition, returns May 14-16, 2019. With more than 500 exhibitors, complimentary conference sessions, industry keynotes and much more, EASTEC is an event dedicated to keeping northeast manufacturers competitive.

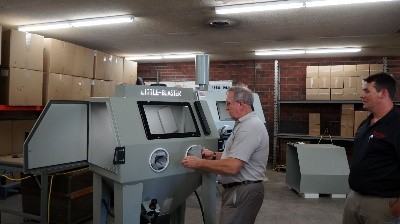

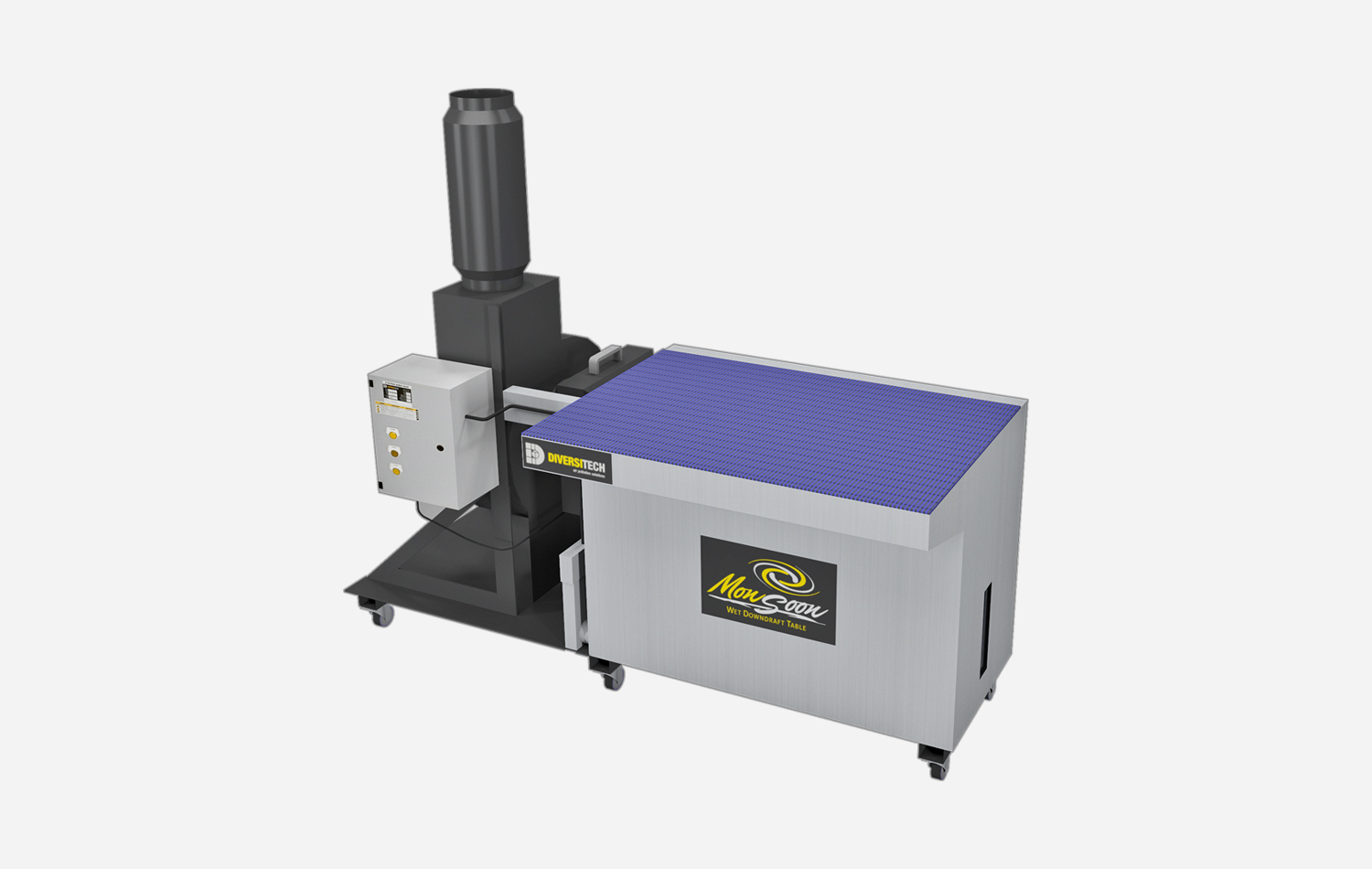

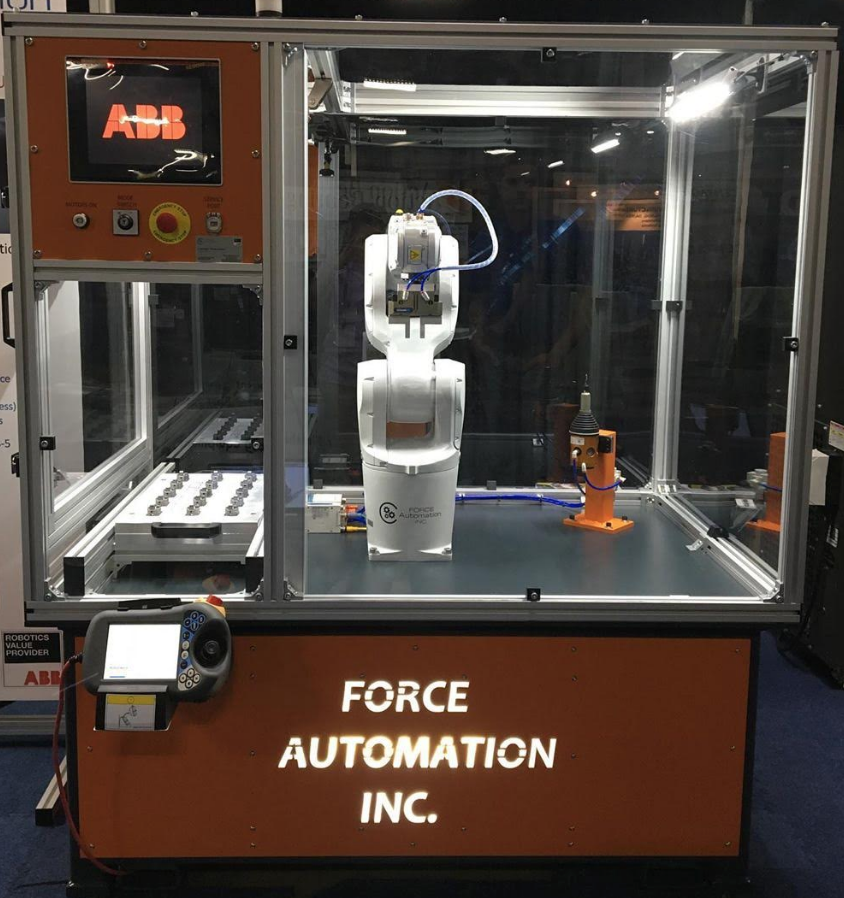

It’s where manufacturing ideas, processes and products that make an impact in the northeast region, are highlighted through exhibits, education and networking events. The event offers a unique chance to connect with resources that can solve your company’s most pressing problems, improve productivity and increase profits. It’s clear why so many business owners, engineers, designers, production managers and purchasing executives attend EASTEC to keep their operations current. EASTEC brings human ingenuity and manufacturing brilliance together. Make sure it’s part of your strategy and reserve the dates on your calendar! We have the biggest finishing booth – #5509!