As you know, Jenfab has been working over the past year on its new Orca roll-in door parts washing system. Today, we are happy to announce that the Orca is in production and will be phased into distribution starting this May.

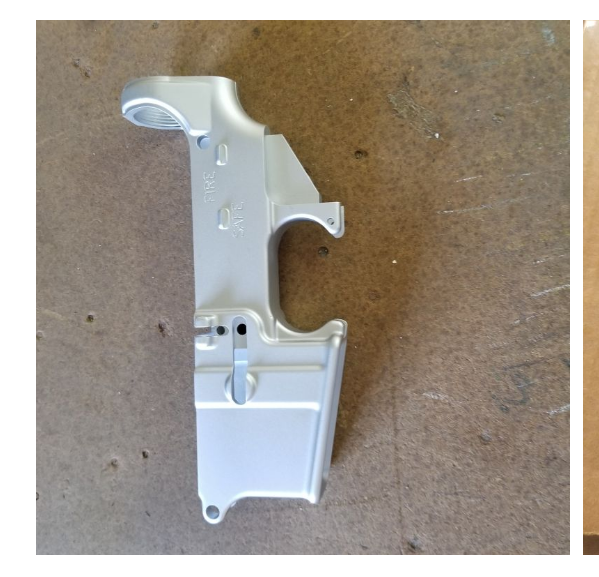

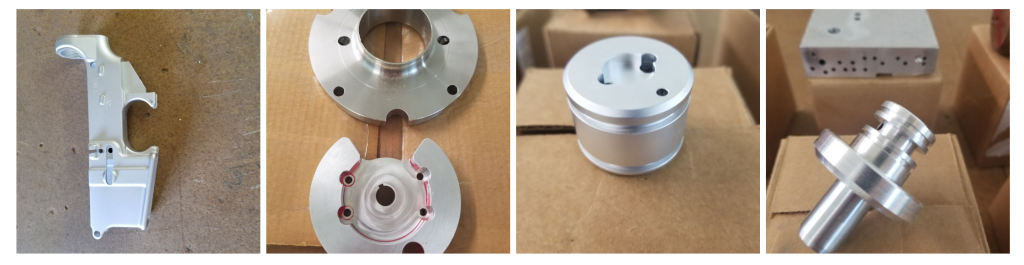

We are very excited about this new system and are certain you will find it to be one of the best Jenfab has ever offered. Why? Because the Orca isn’t just another parts washer. We have designed it specifically to take on and beat the competition.

To achieve this goal, we took a look at our competitors and asked ourselves what we could do to be better. The result is a parts washer with more standard features than the competition combined with unrivaled quality, all at a competitive price. In addition, the Orca will be delivered within two weeks (10 business days) from the time of order.

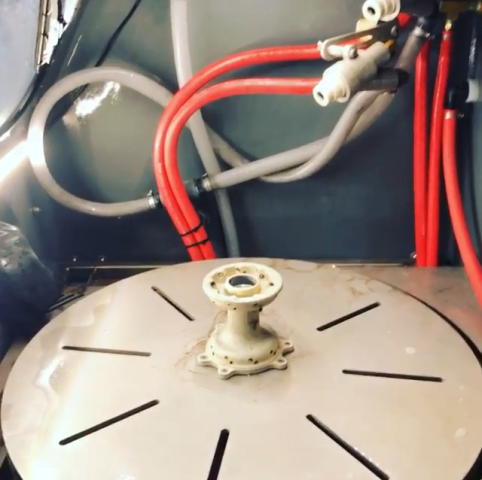

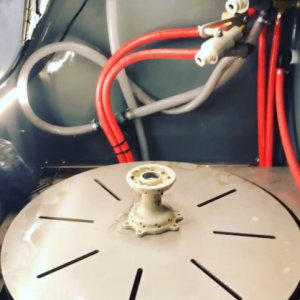

The Orca will come in three standard turntable sizes of 25″, 31″ and 36″ with the 31″ design being offered first and the other two following soon after. It is built for light to heavy-duty, industrial cleaning and features a space-saving roll-in door design. Depending on the model, it can handle between 1,000-1,500 lbs. loads and uses Jenfab’s standard sprocket driven turntable and swing-down spray bar design. For additional system specifications, you can download the brochure below.

Jenfab is anticipating a huge demand for these systems and is now taking pre-orders from any distributor that has a need. Should you have any questions or wish to pre-order a system between now and the time the Orca becomes available, please contact your regional sales manager.

We appreciate your efforts as a Jenfab distributor and hope we can continue working together to make the Orca a success.