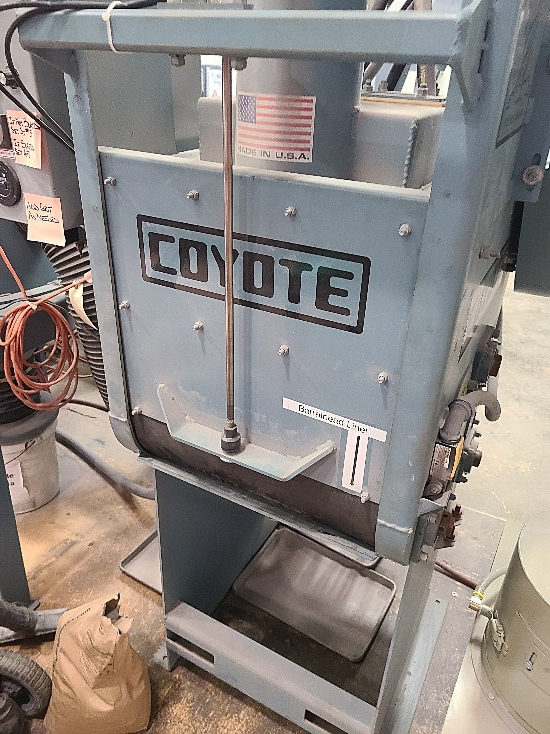

Blast-It-All Tumble Blast System with Dust Collector

BB-2 22″ Wide x 30″ Diameter

Only 264 hours of production on the machine – excellent condition

CABINET: Constructed of high-quality 12-gauge steel

BARREL: Constructed of a 11-gauge carbon steel. Access to parts loading and unloading is through a removable door, held in place by cam type clamps for security. Barrel is 22″ Width x 30″ Diameter with (2) Blast Guns – #6

CABINET DOOR: One, full opening, swing type mounted on heavy-duty hinges

GUN: The BB-2 uses two (2) stationary production-style guns, suction feed. A number six air-orifice and carbide nozzle is installed as standard, other sizes and types are available depending upon compressed air supply. All hoses are 5/8″ ID, lightweight, clear, flexible, and abrasive resistant. Media/Air Blast ration is obtained by a fixed media feed valve.

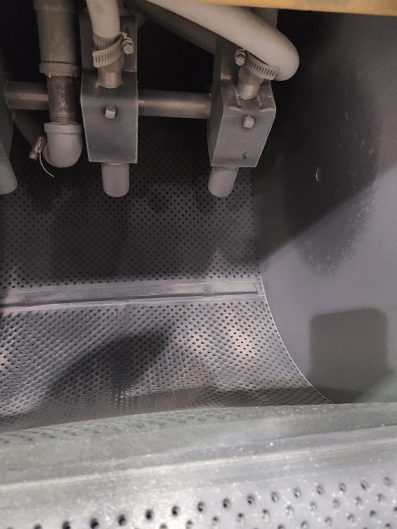

RECLAIM SYSTEM: High efficiency centrifugal type, with an adjustable air wash and trash screen to trap large debris. A high-performance blower is used to convey media and blasting by-products to the reclaim for separation.

M4DC – 4 Cartridge 700 CFM Dust Collector: The M series collectors are of cartridge type with auto cleaning and are designed and built for continuous duty operation. The units are designed for use with abrasive blast systems.

CONTRUCTION: Standard construction of the unit is 11-gauge hot rolled steel,reinforced to maintain structural integrity to 15″ w.g. all wiring, air piping, solenoids and valves are mounted externally. Inlet sizes 6″ through 8″.

FILTER CARTRIDGES: Filters are replaceable cartridges. Each filter has approximately 103 square ft of filter media. Pulse cleaning: an adjustable timer for controlling the “on”and “off” time of the air pulse is enclosed in a Nema-12 control panel. A Magnahelic gauge is provided for monitoring the differential pressure drop. Magnahelic to show differential pressure through dust collector

FEATURES:

D.C. Variable Speed Control

Sequence Lights

Panel Disconnect

Front-Unloading Door

Cost of BB-2 with M4 Dust Collector : $19,500

Terms: Full payment prior to shipping. FOB, Massachusetts.

Purchase Order, Deposit, Final Balance needs to be made out and paid to:

Blast & Wash Systems

9401 State Rte 21

Wayland NY 14572

Demo and Used Equipment Disclaimer: The goods described herein as “Demo” or “ Used” are offered “as is”, “where is” unless otherwise noted. Blast & Wash Systems (designated herein “seller”) makes no warranties of any kind whatever, expressed or implied, or merchant-ability and fitness for a purpose. All specifications and description of said goods are approximate only. It is the Buyers responsibility to inspect the

goods and ascertain if the specifications, description and condition of the goods conform to Buyer’s requirements.

Machine use and safety

Buyer acknowledges that the goods described herein as “demo” or “used” equipment are neither designed nor manufactured by the seller. Seller has no knowledge of, or control over the prior use or misuse of said goods, nor does the Seller have knowledge or control over the future application of these goods by the Buyer. It is the Buyer’s (user’s) responsibility to provide proper safety devices, equipment and instructions for any use and to take all necessary steps to conform to all federal, state or local government safety standards including OSHA.

Indemnification

Buyer agrees to indemnify, hold harmless and defend Seller of and from all claims, liabilities and damages from any accidents or other incidents involving the goods described herein.