Wet Blasting Success

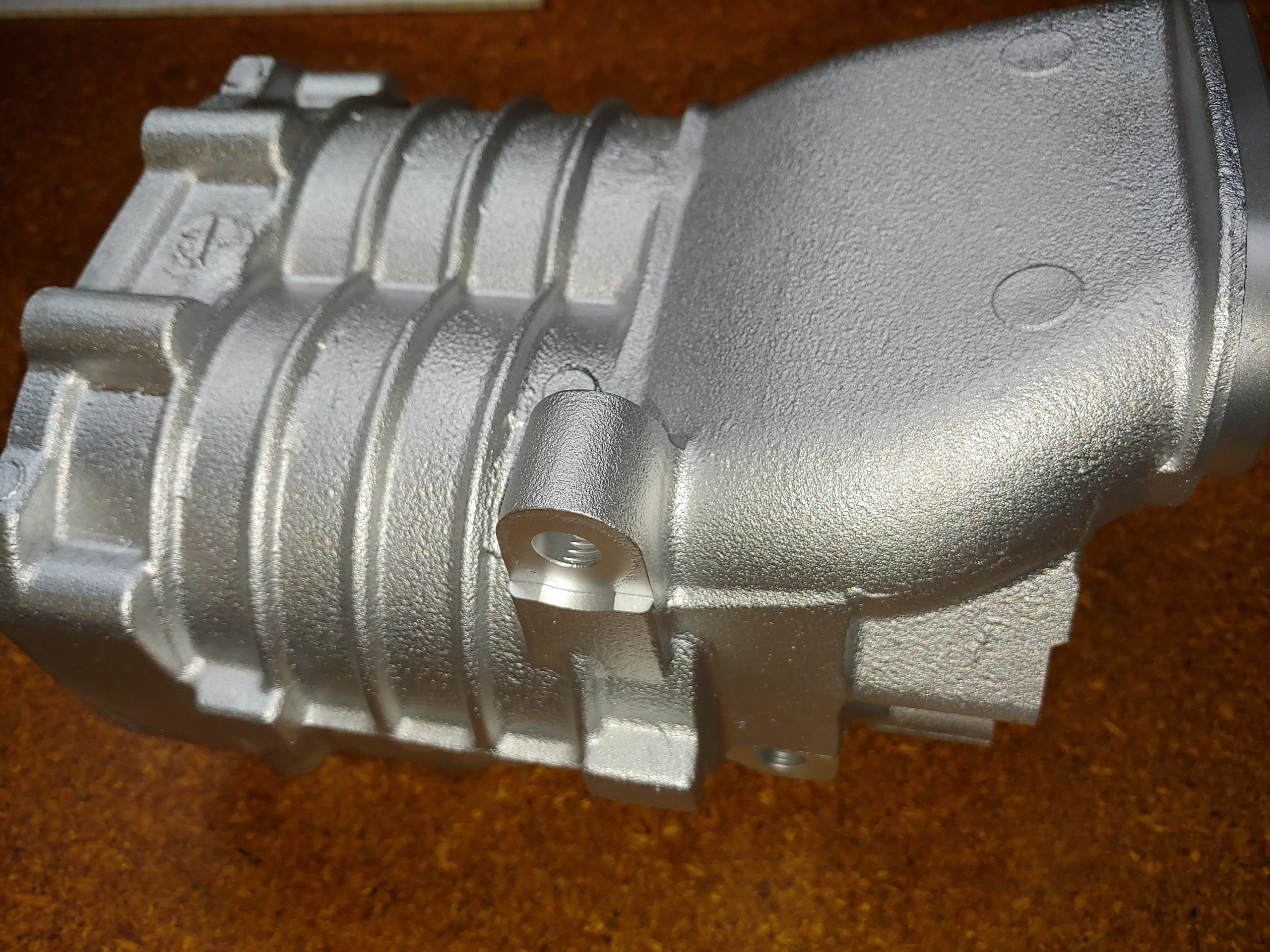

Before

After

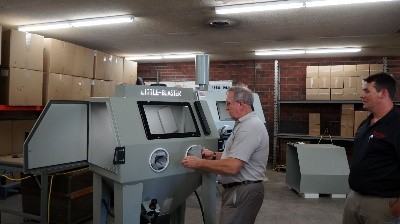

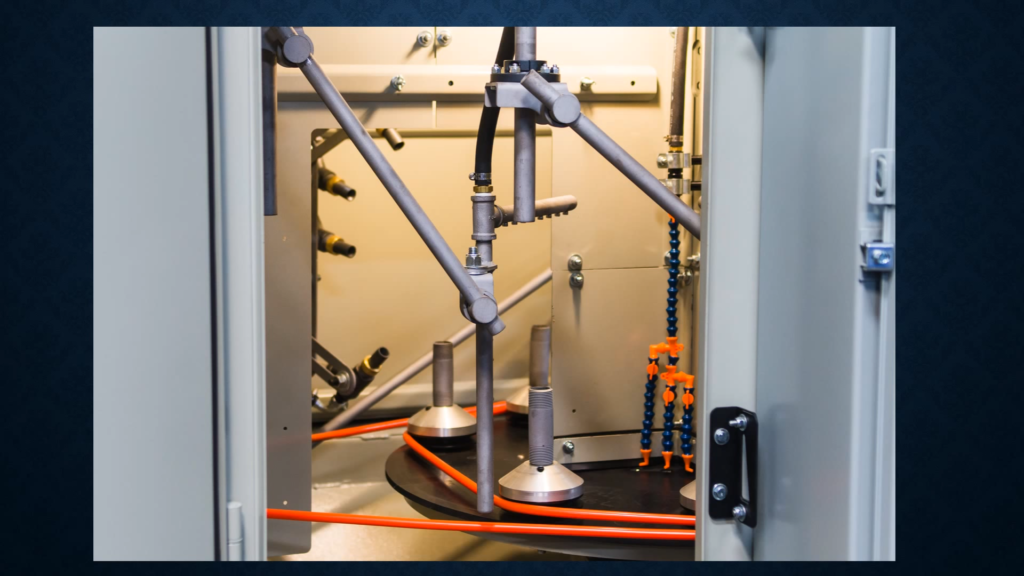

Terry Hopkins (Blast & Wash System’s President) spoke to me about an automotive rebuild shop that he had visited. Terry knew that the wetblast process is an excellent way to clean, peen and shine aluminum parts. After discussing the project with Terry we both felt that we should put-our-best-foot-forward which in this case meant getting some parts into my lab for blasting.

Parts arrived a few weeks later. There was a combination of aluminum parts including a turbo charger and super charger parts. We asked the customer to send the parts as disassembled without any pre-cleaning. The beauty of the wetblast process over dry is as follows.

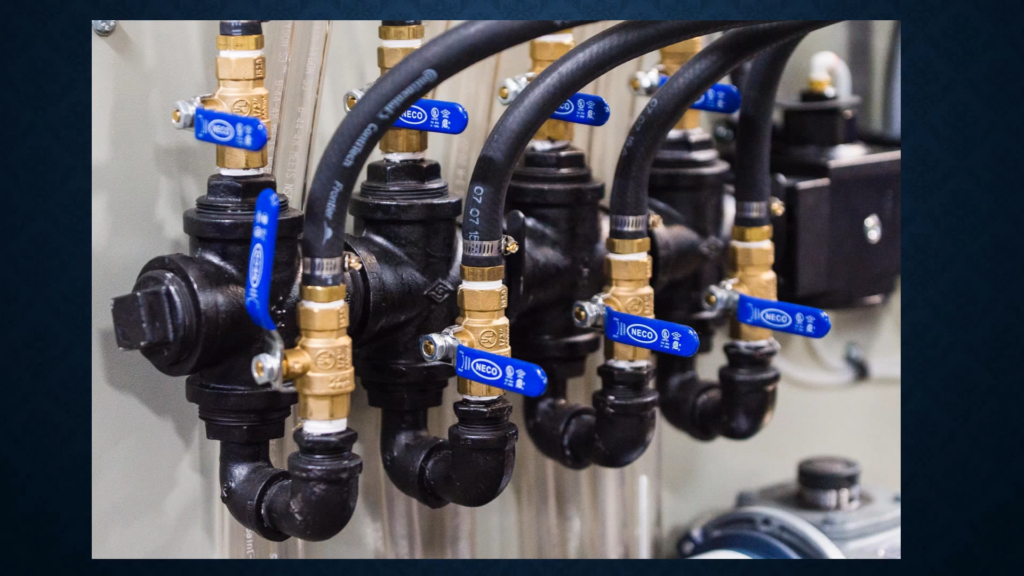

- Precleaning is not necessary. Wetblast cleans and filters oil and scum whereas a dry blast machine would plug up very quickly.

- The wetblast process is much more consistent over dry. The slurry fed to the blast gun is blended so well that you eliminate the “hot spot” streaks that you often see in dry blast

- No more airborne dust all over your shop!!!!

The parts were all done in less than five minutes each. The scum just made its way out to the closed loop rinse system where it was filtered. The blasted surface is “peened” so no more fingerprints or oil stains. Any oil or contamination will just wipe right off. Nine times out of ten the parts are much better than from the factory.

Written by Rick Paul from wetblasting.com