Vapor blasting aluminum is hands down one of the best ways to either add a surface finish or prepare the surface for coatings. Most aluminum’s being very soft can be damaged easily when processing by other traditional methods. Vapor blasting aluminum is non destructive meaning you can hold tight tolerances, will not damage sealing surfaces, and will not impregnate into the surface which can cause many other issues when post processing. Whether you will be blasting aluminum extrusion, or machined parts there is a vapor honing solution that fits well with your application.

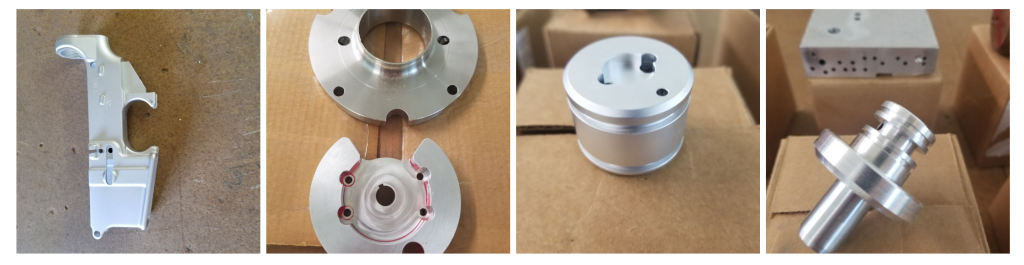

Below are some videos on processing aluminum machined parts and the results you can expect. In these examples we were completing two different tasks the first de burring and the second was providing a consistent even finish on the parts. The wet blast system makes consistency a breeze because on the flow based nature of the process. Imagine spraying a water hose at a part under 60- 70 PSI and how easily it would be to replicate these results due to the flow of water and how it contacts the surface. Since vapor blasting is flow based it also adds a few other benefits such as no heat warping, no hot spots when blasting and less wear on consumables. There are other machine related benefits too such as better ergonomics, Lower decibel levels, and lower dust levels contaminating the work environment inevitably contaminating processed parts as well. We are here to help walk you through the different techniques and equipment options to see what works best for you and your application. If you would like to test a particular application or compare quotes on our different slurry blasting systems please email us.

– Vapor Honing Technologies