VHT Gladiator

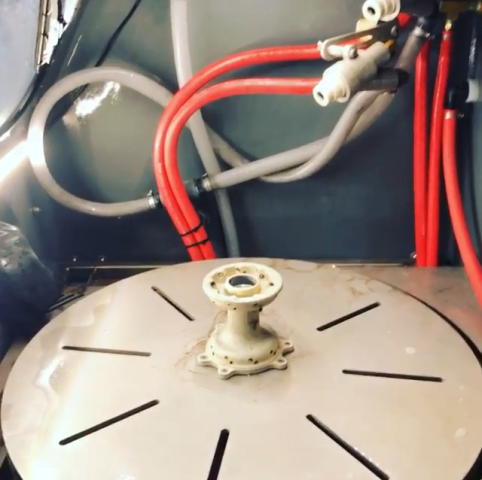

Vapor Honing Technologies Gladiator Your browser does not support the video tag. Gladiator table - All in one- Wet blast, Wash, Rinse and Dry Now you can Vapor Hone your parts automatically In this versatile system by placing parts on the powdered turntable – fully programmable! Inset a fixture on the turntable and you can [...]

Robotic Vapor Honing System with Teach Pendant

Robotic Vapor Honing System with Teach Pendant We are happy to introduce the latest in wet blast technology. Vapor Honing has released The Robotic VH System. This unit is very cost effective and has many features designed to make it simple to use! Training is available to teach users the technology to ensure proper use [...]

Die Casting & Oil Mist/Smoke Solutions

Die Casting & Oil Mist/Smoke Solutions Employees working with die casting processes are often exposed to high concentrations of oil fumes and mist. At the beginning of the die casting sequence, lubricant is sprayed onto the die cavities, the mechanical plunger and the die guide bars. Due to the elevated temperature of the dies, some [...]

Vapor Blasting Rusty Parts

Vapor Blasting Rusty Parts CT’s Garage used Vapor Honing Technologies wet abrasive blast cabinet called the “Weekend Warrior” to restore parts from a VW bus back in December of 2019. To date it has received over 218,000 YouTube hits. You’ll see a step by step process on how parts that are old, rusty and [...]

Jenfab Launches New Orca Parts Washing System

Jenfab Launches New Orca Parts Washing System As you know, Jenfab has been working over the past year on its new Orca roll-in door parts washing system. Today, we are happy to announce that the Orca is in production and will be phased into distribution starting this May. We are very excited about this new [...]

Wet Blast Automation

Simply Affordable Wet Blast Automation! Finally, we have automation & innovation that is really affordable! Vapor Honing has just introduced an automated wet blast system that will save hundreds of repetitive motion man hours. Instead of standing at a blast cabinet with hands fully engaged in blasting for hours, you can now set your program [...]

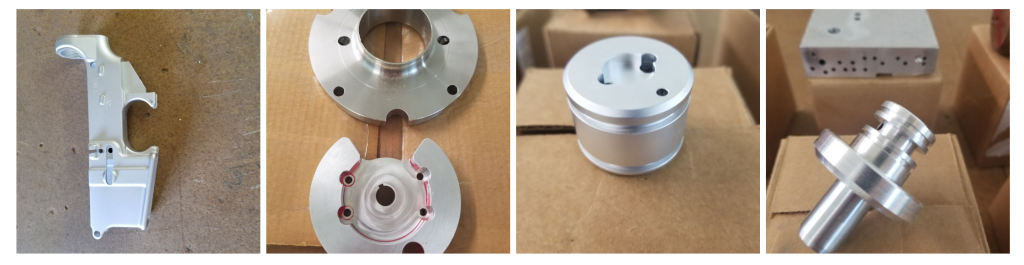

Vapor Blasting Aluminum

Vapor blasting aluminum is hands down one of the best ways to either add a surface finish or prepare the surface for coatings. Most aluminum’s being very soft can be damaged easily when processing by other traditional methods. Vapor blasting aluminum is non destructive meaning you can hold tight tolerances, will not damage sealing surfaces, [...]

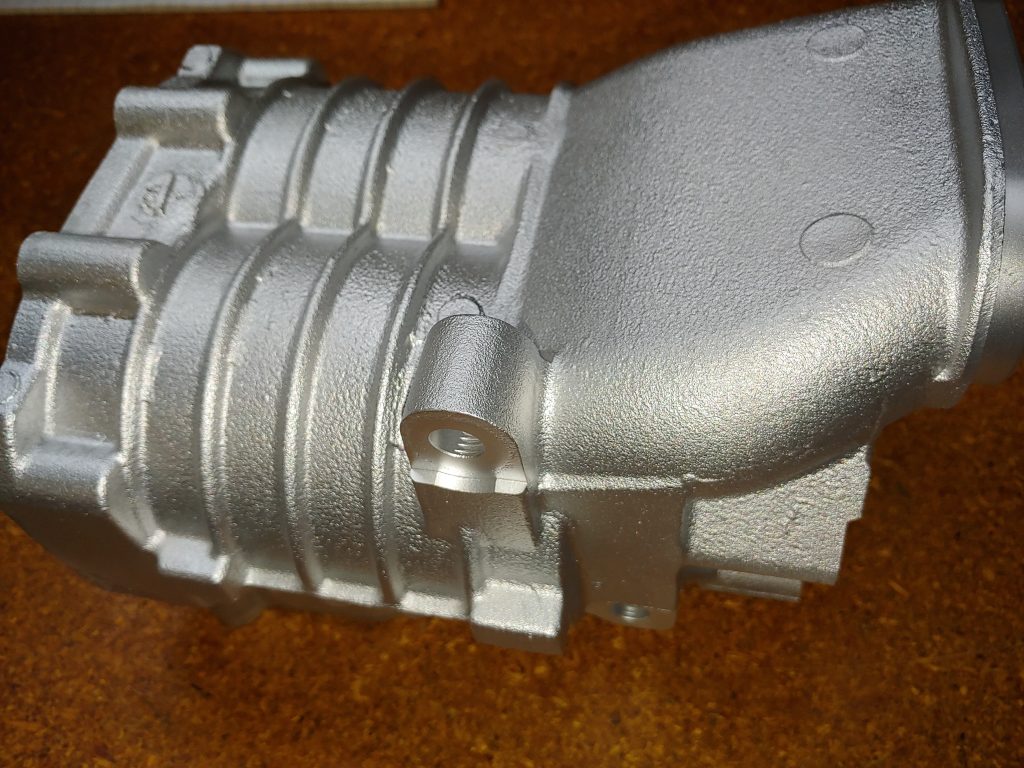

Supercharger Wet Blasting Success

Terry Hopkins (Blast & Wash System’s President) spoke to me about an automotive rebuild shop that he had visited. Terry knew that the wetblast process is an excellent way to clean, peen and shine aluminum parts. After discussing the project with Terry we both felt that we should put-our-best-foot-forward which in this case meant getting some parts into my lab for blasting.

Jay Leno’s Garage – Wet Blasting Vapor Honing

Wet Blasting by Vapor Honing Technologies Wet Blasting is by far the fastest growing technology for cleaning metal parts. Blast & Wash Systems is a distributor of wet blasting equipment manufactured by Vapor Honing Technologies. This technology uses water and 173-25 mesh glass beads at 100PSI pressure and ambient temperature [...]

EASTEC 2019 | Blast & Wash Systems

Blast & Wash Systems will be an exhibitor at EASTEC, New England’s premier manufacturing exposition, returns May 14-16, 2019. With more than 500 exhibitors, complimentary conference sessions, industry keynotes and much more, EASTEC is an event dedicated to keeping northeast manufacturers competitive. It’s where manufacturing ideas, processes and products that make an impact in the [...]

2018 Manufactured in Vermont Supply Chain Trade Show

Blast & Wash Systems will be exhibiting in the 2018 Manufactured in Vermont Supply Chain Trade Show on Thursday, September 27 at the Champlain Valley Expo Center, Essex Junction, VT. We will be located in booths 614, 616. We’ll have blast, vibratory and air filtration equipment at the show. Equipment in the booth included a Blast it All […]

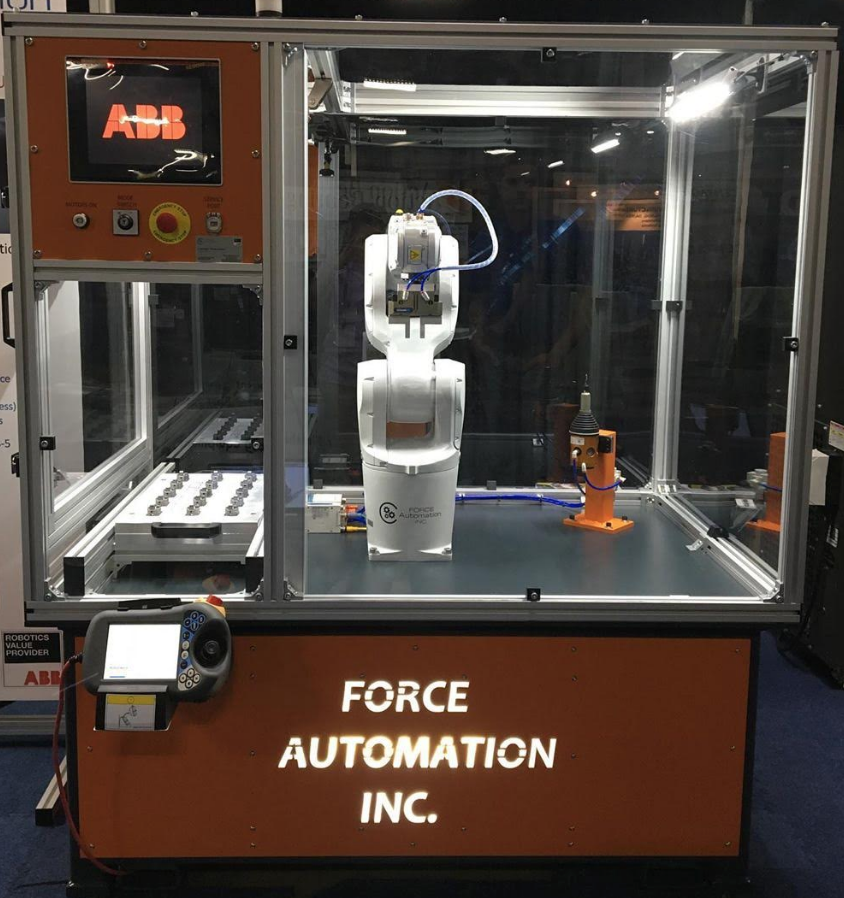

Press Release – Blast & Wash Systems Partners with Force Automation, Inc.

Press Release – Blast & Wash Systems Partners with Force Automation, Inc. Press Release – July 9th, 2018 Blast & Wash Systems announced today a partnership with Force Automation, Inc. in providing robotic integration for industrial parts finishing. Terry Hopkins, President of Blast & Wash Systems, commented on the partnership: “We have found a natural […]

Winner of the Golden Fred Award

The Golden Fred Award Blast & Wash Systems is proud to be the recipient of the 2016-17 Golden Fred Award by DiversiTech Industrial Air Filtration Equipment in recognition of our sales exceeding $250k! Please Contact Us at Blast & Wash Systems about your industrial air filtration needs. Our coverage includes Rochester, Elmira, Buffalo, & Syracuse [...]

Press Release – Blast & Wash Systems doubles distribution territory

Press Release – Blast & Wash Systems doubles distribution territory February 15, 2017 …. Blast & Wash Systems is expanding its distribution territory/geographical coverage; added an engineering corporate partner and hired a senior management professional. Blast & Wash Systems based in New York State has distribution coverage throughout New England, New York, New Jersey, Pennsylvania […]

Blast It All ITT-30

Blast It All ITT-30 30 Indexing Turn Table. New Equipment Standard equipment with custom designs… energy efficient impact blasting…in-line capability. Designed for applications such as cleaning castings, forgings, structural steel, and heat treated parts, BLAST-IT-ALL systems give the finish needed and may be programmed to be tied in with existing controls or designed as part of […]

EASTEC 2017 | Blast & Wash Systems

Blast & Wash Systems will be an exhibitor at EASTEC, New England’s premier manufacturing exposition, returns May 16-18, 2017. With more than 500 exhibitors, complimentary conference sessions, industry keynotes and much more, EASTEC is an event dedicated to keeping northeast manufacturers competitive. It’s where manufacturing ideas, processes and products that make an impact in the […]

Aquablast®915 Designed by Vixen

Aquablast® 915 The Aquablast® 915 wet blasting machine is designed by Vixen to simultaneously de-grease and blast multiple components. Customers find this to be an excellent entry-level wet blasting machine. The process cleans by flow, and not impact, producing a ‘soft’ finish. The water acts as a lubricant, avoiding media impregnation and also extending the life […]

PRI International Motorsports Trade Seminar – Dec 9th

International Motorsports Trade Seminar Fri. December 9| 10:00 AM – 11:30 AM | Indiana Convention Center, Room 234 A panel of top international buyers and top manufacturers selling internationally, led by Wilfried Eibach of Eibach Springs, Brian Patrias of Motovocity, Rob Herrod of Ford Racing Parts Australia & SCT Australia and Darrick Dong of Performance […]

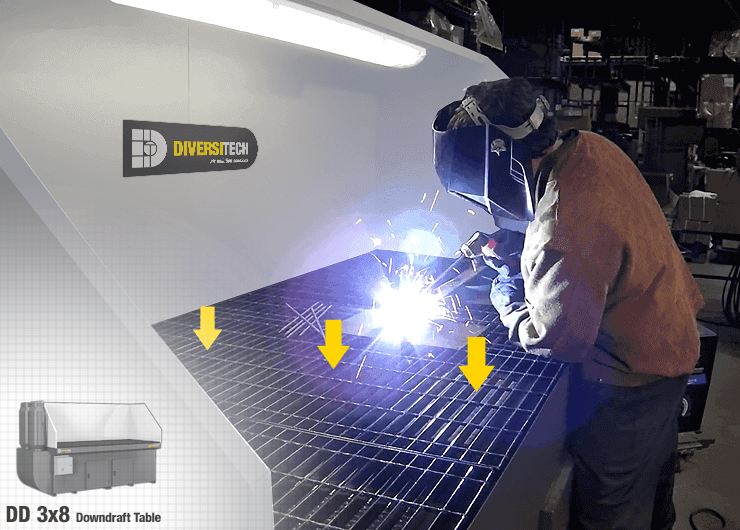

Diversitech Air Pollution Solutions

Diversitech Air Pollution Solutions A technology leader in the Air Filtration & Dust Collection industry, Diversitech Air Pollution Solutions delivers reliable products manufactured to perform correctly in your application. Keeping Unbreathables away from the operator’s repository zone requires capture-at-source equipment that is easy-to-use, easier-to-service, and is powerful enough to return truly clean air. Airborne contaminants are […]

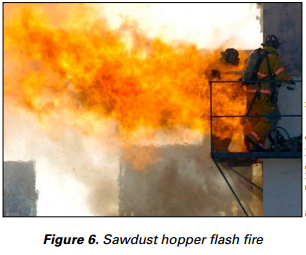

OSHA: Combustible Dust Hazard

Combustible dusts are fine particles that present an explosion hazard when suspended in air in certain conditions. A dust explosion can be catastrophic and cause employee deaths, injuries, and destruction of entire buildings. In many combustible dust incidents, employers and employees were unaware that a hazard even existed. It is important to determine if your […]